The Journey of a Solar Panel: From Factory to Installation

At SWELECT, every solar panel’s journey begins at our state-of-the-art 1 GW+ manufacturing facility in Coimbatore. Here, advanced automation and rigorous quality control measures ensure that each panel meets our high standards of efficiency and durability. Let’s take a behind-the-scenes look at this process.

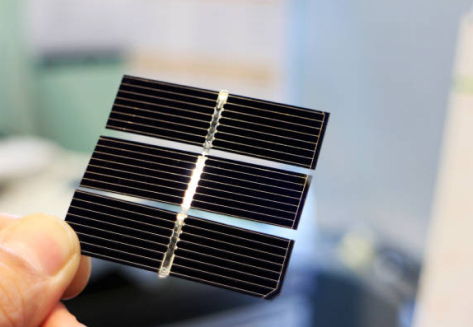

The journey starts with raw materials, including high-grade silicon, carefully selected to form the solar cells. These cells are created using precise technology, where they are treated, cut, and assembled into modules. Our fully automated production lines streamline this process, ensuring maximum precision and consistency.

Next comes the assembly phase. Cells are arranged and encapsulated to form the core of the solar panel. The use of advanced materials, such as anti-reflective coatings and high-transparency glass, enhances the panel's efficiency. Once assembled, the panels undergo a series of rigorous quality control tests to ensure they meet international standards. These tests include exposure to extreme weather conditions and load-bearing assessments to verify their durability.

Once a panel passes these stringent tests, it’s ready for shipment. Panels are securely transported to installation sites, where SWELECT’s expert teams ensure seamless integration into solar energy systems, whether for residential rooftops or large-scale industrial applications.

At SWELECT, we take pride in not just manufacturing solar panels but crafting solutions designed for performance and longevity. Each step in the process is meticulously managed, ensuring that every panel we produce contributes to a sustainable, energy-efficient future.